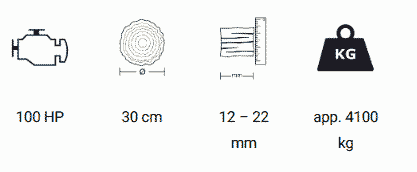

Greentec Drum Woodchipper – Efficient, Rugged, and Built to Perform

Designed for Practical Performance

This woodchipper is all about getting the job done — no gimmicks, no fluff. Chipping at the front, discharge at the rear, just the way it should be.

-

Integrated Hydraulic Cooling

The chipper features its own hydraulic cooling system, using Venturi airflow to regulate temperature efficiently — no extra fans required.

-

Powerful Blowing System

A combination of Venturi and integrated blower systems ensures a strong and consistent airstream, efficiently moving chips through the chute without blockages.

-

Simple, Efficient Operation

No need for jacks or accelerators that can break down chips or add unnecessary wear. This streamlined setup reduces fuel use, power demand, and maintenance, boosting overall efficiency.

-

Consistently High Chip Quality

Greentec drum woodchippers are known for producing uniform woodchips with minimal fine particles, making them ideal for biomass and clean mulch applications.

Drum System – Built for Long-Term Reliability

-

Knife Configuration

Knives are strategically spaced along the drum, which also includes blower blades on both sides to aid chip expulsion.

-

Widia Bottom Knife

A hardwearing Widia blade sits just below the main cutting knife and is easily accessible for maintenance.

-

Heavy-Duty Construction

The 15 mm-thick drum wall and Ø100 mm main axle deliver rock-solid performance, even under heavy loads.

-

Optimised Anvil Knife

The specially designed anvil knife slices small branches at a refined angle, resulting in cleaner cuts and better chip quality.

Infeed System – Smooth and Strong

-

Lowered Infeed Table

Designed for ease of use, the lowered table gives extra space to insert larger logs using clamps or grabs.

-

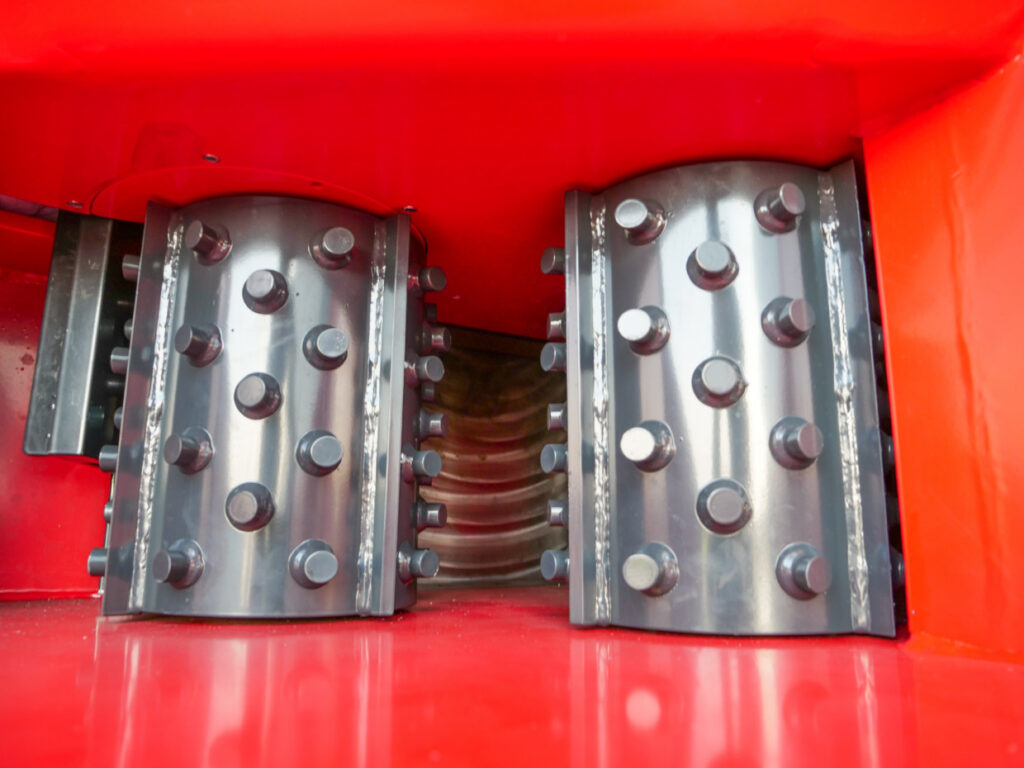

Upper Infeed Rollers

Dual upper rollers are driven by high-torque motors with embedded oiled bearings, reducing maintenance needs while delivering aggressive feed performance.

-

Maintenance-Free Bottom Roller

The bottom infeed roller is powered by a heavy-duty torque engine with sealed oil-lubricated bearings — built to run hard, with zero fuss.

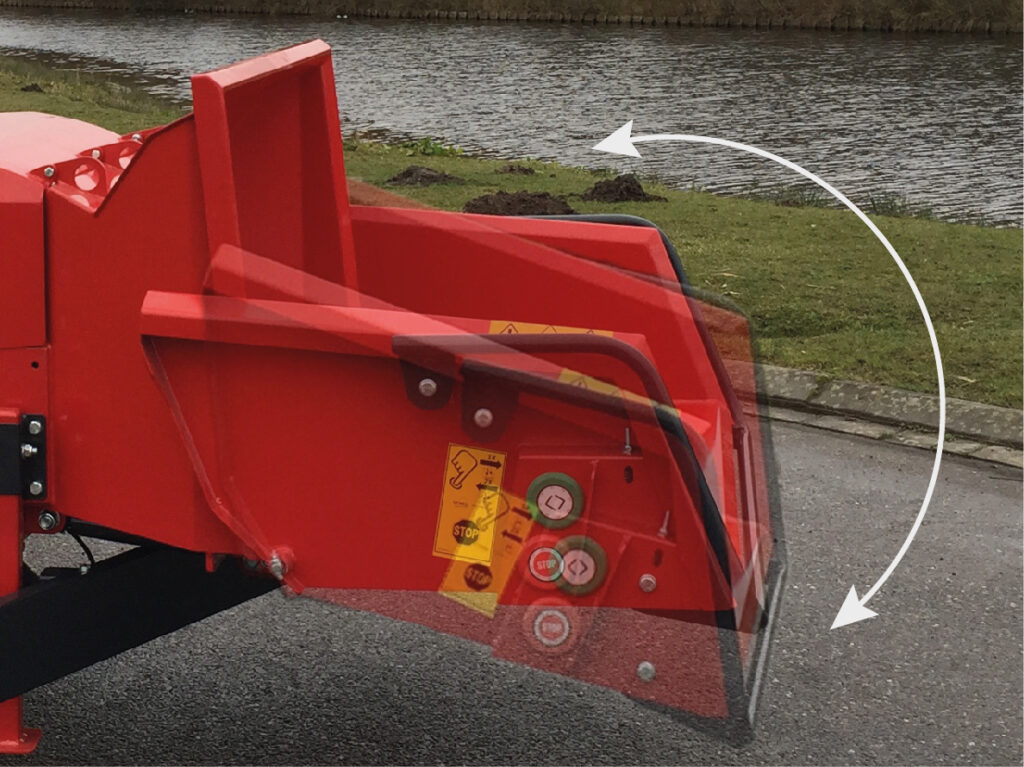

Screen Unit – Easy Access When You Need It

Top-Notch Build Quality

-

Premium Steel Frame

All machines are built from S355 (52-3) high-strength structural steel — tough enough for Australian worksites.

-

Hardox Components

-

Infeed roller teeth are made from abrasion-resistant Hardox for long-lasting performance.

-

A replaceable Hardox wear plate is installed between the bottom roller and anvil under the drum to protect high-wear areas.

-

Durable Parts Throughout

Every part — from pumps to bearings, engines to valves — is chosen for long life and tough conditions.

-

Corrosion-Resistant Coating

After sandblasting, the machine is double powder-coated for superior protection against the elements.

Easy Servicing & Maintenance

-

Quick Knife Access

Knives are easily accessed under a hinged top cover, making maintenance straightforward and safe.

-

Secured Drum for Blade Changes

The drum can be securely locked in place for safe and simple knife replacement.

-

Reusable Anvil Knife

The adjustable anvil knife can be rotated and reused up to four times, giving you excellent value and reducing downtime.