Greentec 962 Track – Serious Power, Built for Aussie Conditions

The Greentec 962 Track is built tough for demanding jobs in forestry and land clearing. With heavy-duty features and smart tech onboard, it’s the perfect chipper for professional contractors who need reliable performance on any terrain.

Standard Features – Ready to Work

-

Remote Control + Touchscreen Operation

Comes standard with remote control and the Greentec Control System, featuring a user-friendly touchscreen for full control at your fingertips. -

Massive Infeed Power

Features a large Ø620 mm feed roller powered by a rugged Poclain wheel motor — making feeding smoother, faster, and more efficient even with oversized timber. -

Multiple Emergency Stops

Fitted with emergency stop buttons on both sides and at the front by the engine — safety first on every job. -

Hydraulic Infeed Table

The stable, raisable infeed table can be adjusted into multiple positions for various working setups. -

Hydraulic Discharge Pipe + Electric Deflector

Pipe adjusts up and down hydraulically with an electric chip deflector to control chip direction with precision. -

Hydraulic Venturi Chute Tilt

The Venturi discharge chute tilts hydraulically for quick and easy sieve unit changes — saving you time on the job. -

Venturi + Integrated Blower System

The combo of Venturi and integrated blower systems ensures a strong and consistent airstream to keep chips moving efficiently:-

Red: High-pressure airflow

-

Blue: Vacuum zone

-

Yellow: Chip movement

-

-

Manual Disc Clutch

Fitted with a manual disc clutch as standard for straightforward mechanical control. -

Easy Knife Access

Quick-change knives are easy to reach when the infeed rollers are raised hydraulically — giving you direct access to both the blade and anvil knife for fast servicing.

Optional Upgrades – Boost Your Productivity

-

Top Roller Ø620 with Dual Standing Infeed Rollers

Massive infeed capacity with a 1450mm opening for serious jobs. -

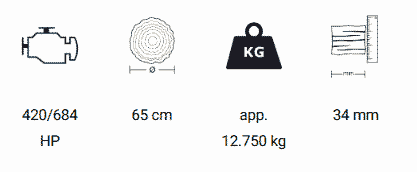

John Deere 684 HP Engine (Tier 4 Final / Stage V)

Fitted with a 13.6L powerhouse engine, complete with an automatic hydraulic clutch for smooth power delivery. -

Closed Infeed Chain with Adjustable Table

The closed infeed chain runs all the way under the top rollers for continuous feeding in all table positions. -

Flexible Reversal Fin

A variable flex reversal fin (9.0 / 420 HP) that helps cut fuel use and noise levels — ideal for long workdays. -

Automatic Hydraulic Clutch Upgrade

Swap out the manual clutch for an automatic hydraulically engaged system for added convenience and performance. -

Rubber on Steel Tracks

Durable rubber-on-steel tracks handle rough Australian terrain with ease, providing excellent grip and stability.