Description

Greentec Cheetah 30/80 – Heavy-Duty Highway Chassis Woodchipper

Built for Road Use – Engineered for Performance

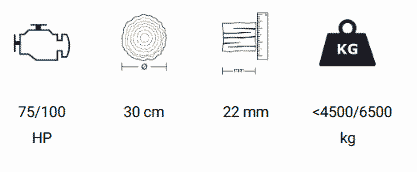

The Greentec Cheetah 30/80 is a powerful and versatile woodchipper mounted on a highway-legal chassis, available in 4.5-ton or 6.5-ton configurations — ready for transport and tough terrain alike.

Standard Features

-

Self-Cooling Hydraulic System

Designed with an innovative hydraulic cooling system that uses the disc blade’s airstream to maintain optimal temperature without extra components. -

Angled Infeed for Greater Efficiency

The angled infeed system reduces power consumption while improving feed efficiency, allowing smoother processing of material. -

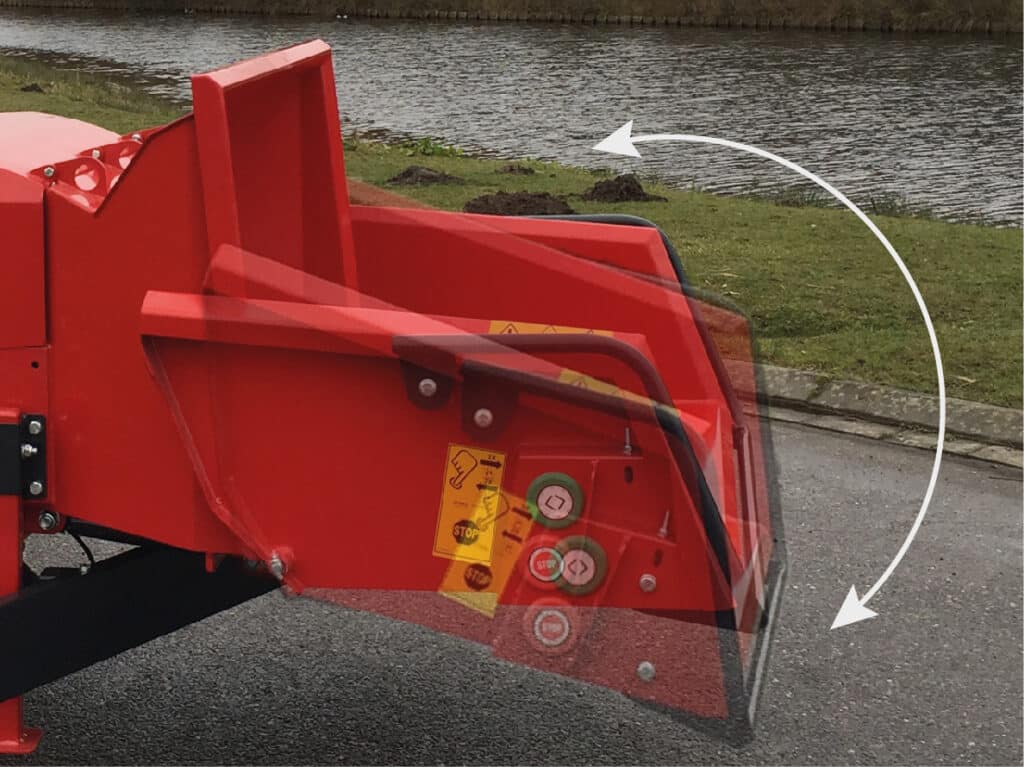

Dual Infeed Options

Features a combination infeed system — manual hand-feed and crane feed, both hydraulically liftable for flexibility and convenience on the job. -

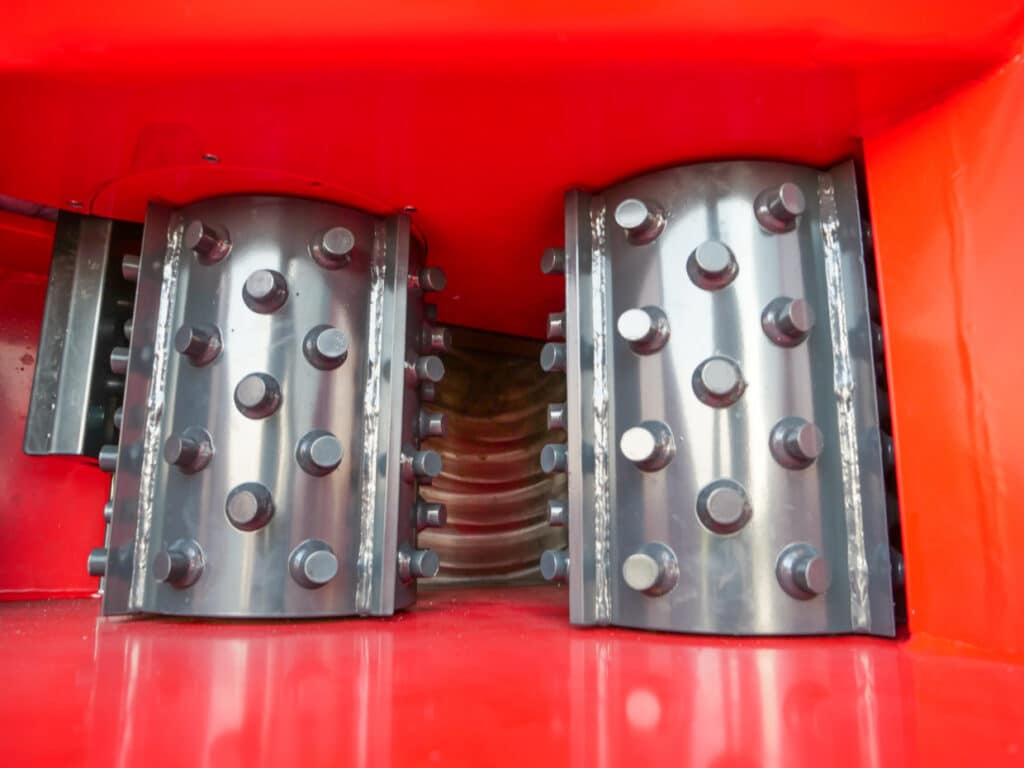

Optimized Chipping Disc

The precision-milled disc is slightly recessed toward each following blade, enhancing infeed speed and minimizing resistance for superior chipping performance.

Built to Last

-

High-Grade Steel Construction

Constructed from S355 (52-3) premium structural steel, ensuring strength, durability, and resistance to wear — even under heavy-duty use.

Maintenance Made Simple

-

Designed with user access in mind, the Cheetah 30/80 offers quick and easy maintenance access points, reducing downtime and maximizing productivity.

Options

- Crane with crane control platform or remote control

- Extra cable control tracks

- Cone holder (long)

- RDW-, TÜV- or PVG-approval